Big data analysis, in-orbit use of artificial intelligence and more. Many future space applications will be dependent on the use of advanced microelectronic components for scientific missions, telecommunications, and Earth observation. In particular, high-performance commercial off-the-shelf (COTS) components and modules, designed for consumer use on the ground, in mobile phones and cars, are very attractive for space missions.

Anticipating the effects of radiation is fundamental when it comes to ensure the reliability of a space mission, but it hardly plays any role in the design of these components meant to be used on the ground. Also, qualifying these complex packaging structures and full electronics boards requires cost-expansive preparation (e.g. de-lidding, thinning).

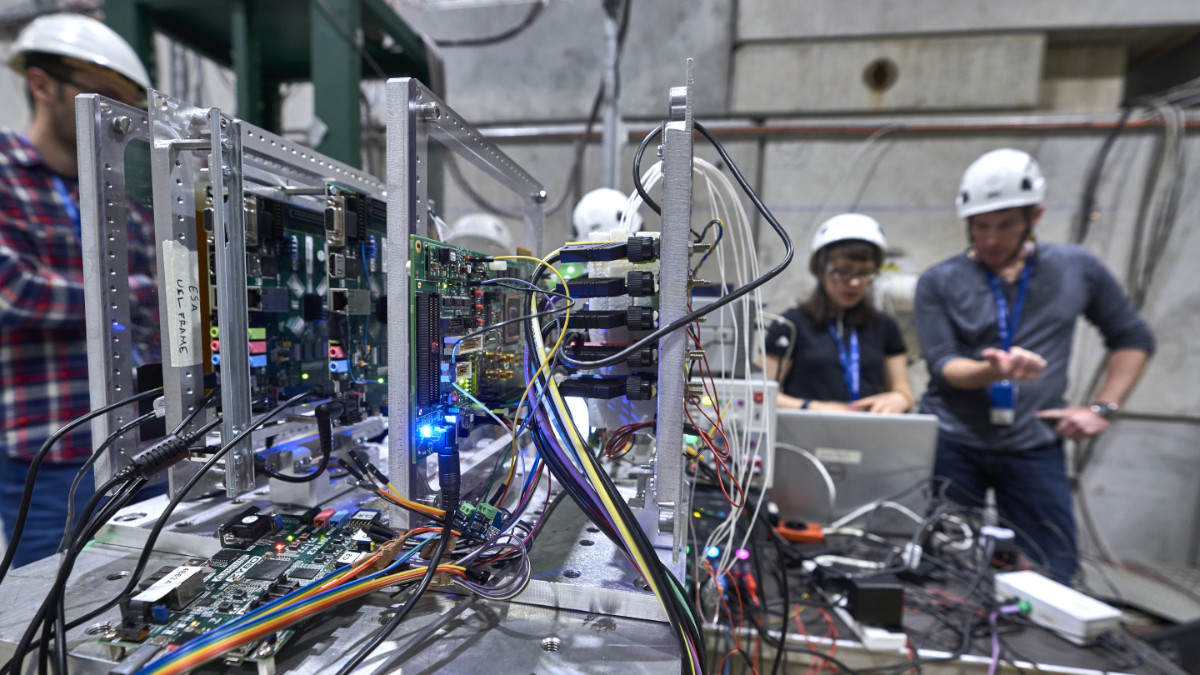

A system-on-chip tested for space applications by ESA at CERN Super Proton Synchrotron (SPS) North Area using a high energy lead-ion beam (Image: CERN, M. Brice).

Until now, the European industry has relied mainly on standard-energy ion beam facilities established in the 1990s and early 2000s. All novel manufacturing practices call for a change in the way radiation effect qualification is achieved. As a result, the demand for VHE heavy ion radiation testing will significantly increase and become very similar to that for standard-energy,

HEARTS project will provide two high-quality, high-energy heavy ion irradiation facilities in Europe, accessible and tailored for space users and applications.

This irradiation offer will foster the utilisation of advanced electronic devices in European space companies, therefore helping the European industry and research infrastructure to place themselves in a very competitive position with respect to the growing worldwide competition.