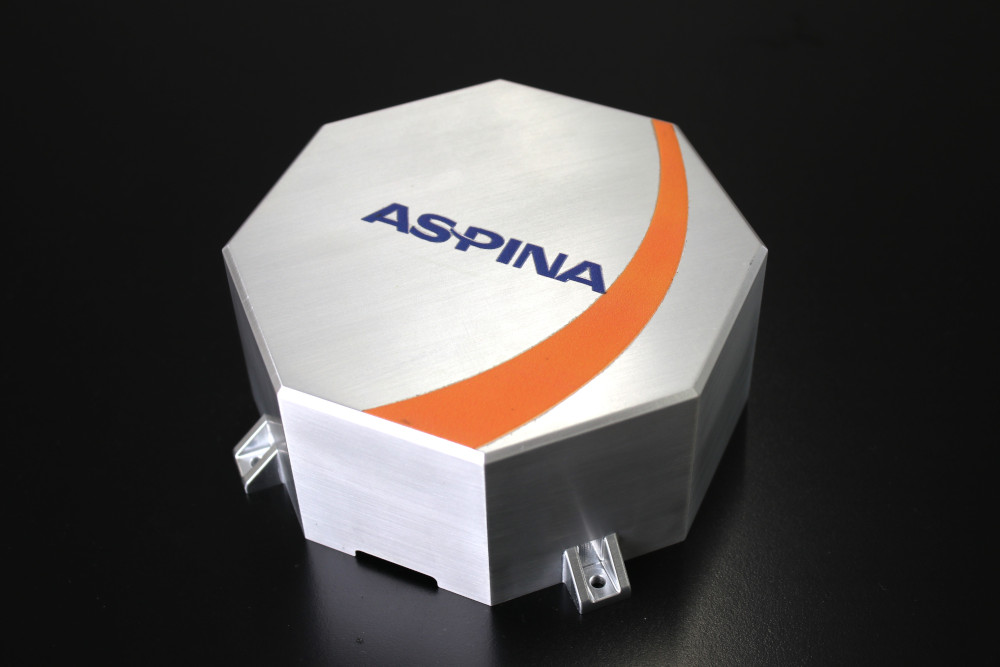

“ASPINA is developing a lineup of reaction wheels for small satellites. While our reaction wheels are qualified for Low Earth Orbit (LEO) applications, we are also interested in meeting the demands for Geosynchronous Orbit (GEO) environments for the larger wheels in our lineup. Typically, satellites that operate in GEO require that no destructive single event effects occur from heavy ions with a linear energy transfer (LET) up to 37 MeV⋅cm2/mg during the lifetime of the mission.

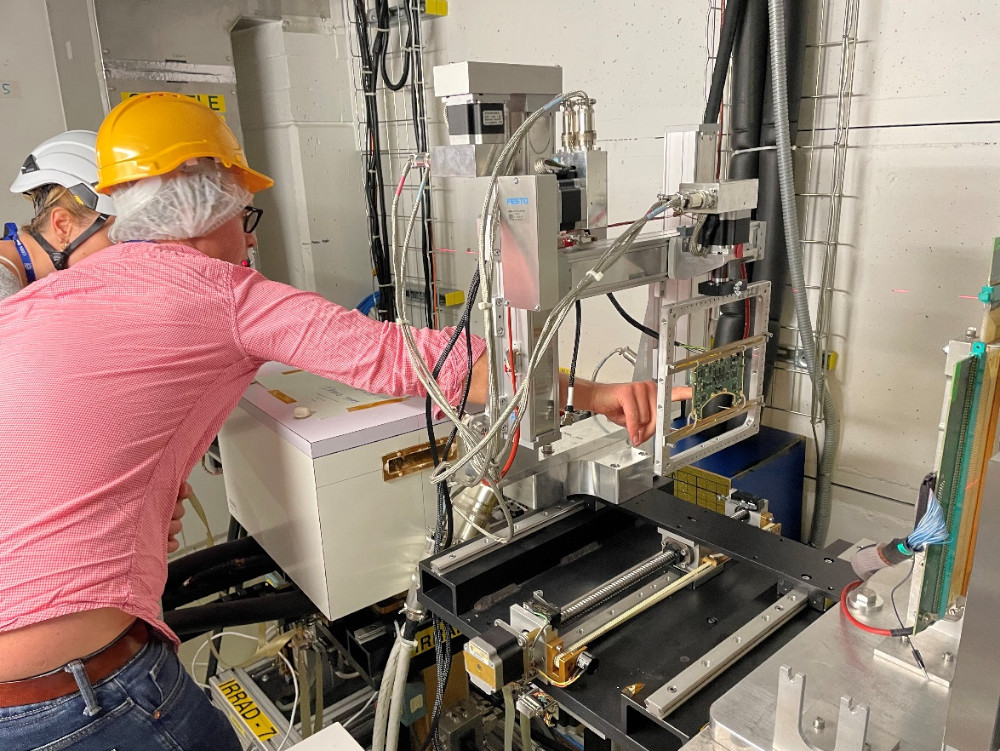

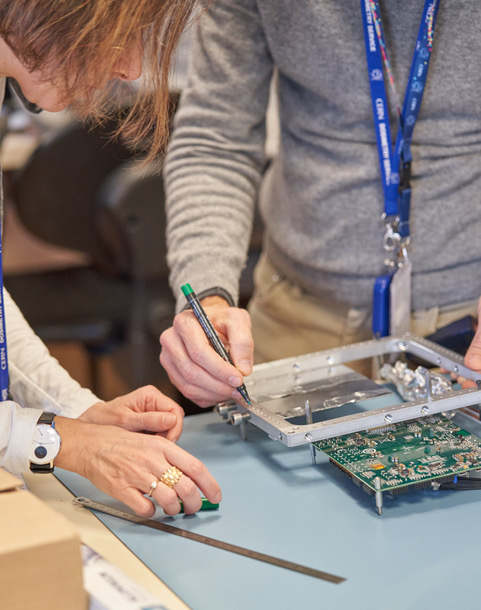

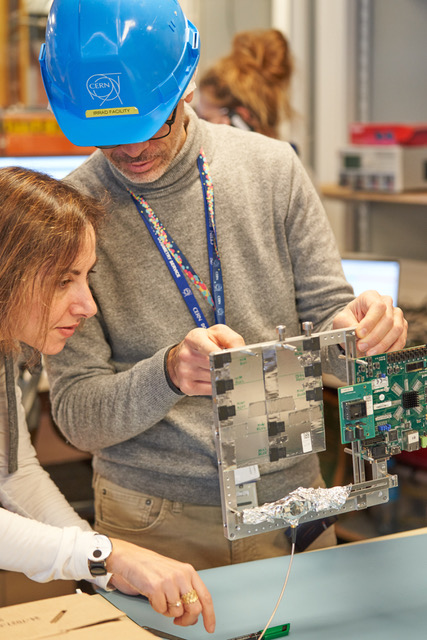

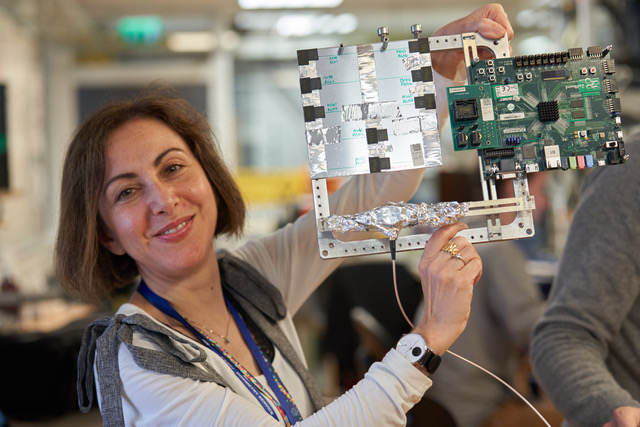

Our reaction wheels contain an integrated driver for motor control, command, and telemetry. Since our intent was primarily to assess the gap between our current parts selection and the requirements of GEO, we wanted to test all the ICs on the front and back of a handful of boards of the same design to generate meaningful statistics without needing a lot of preparation time and beam time.

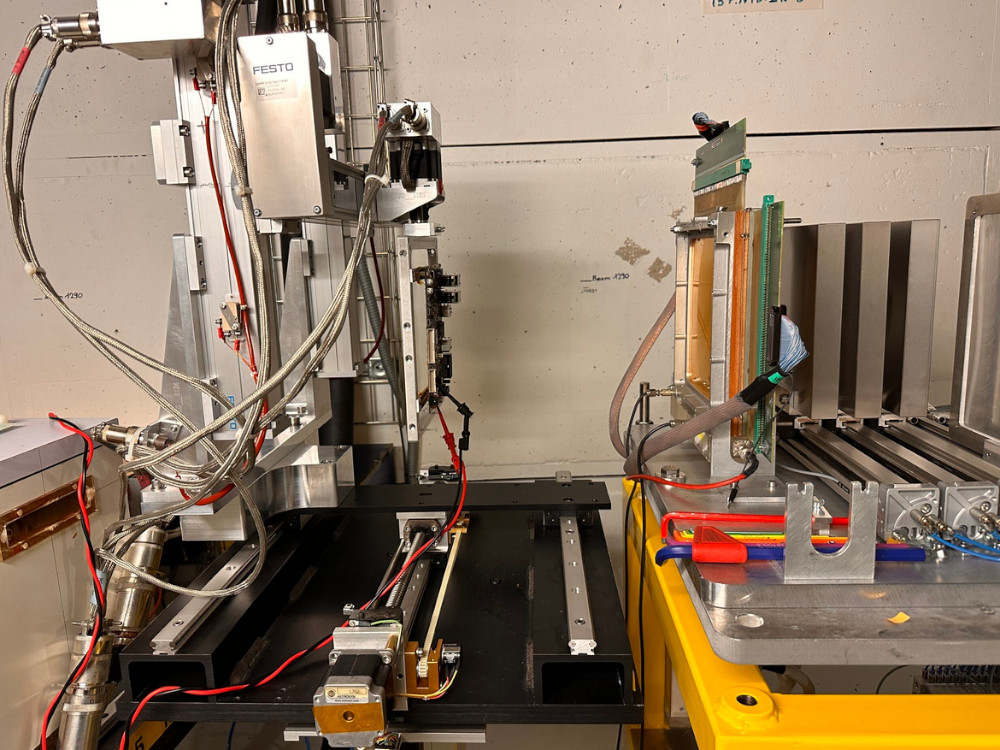

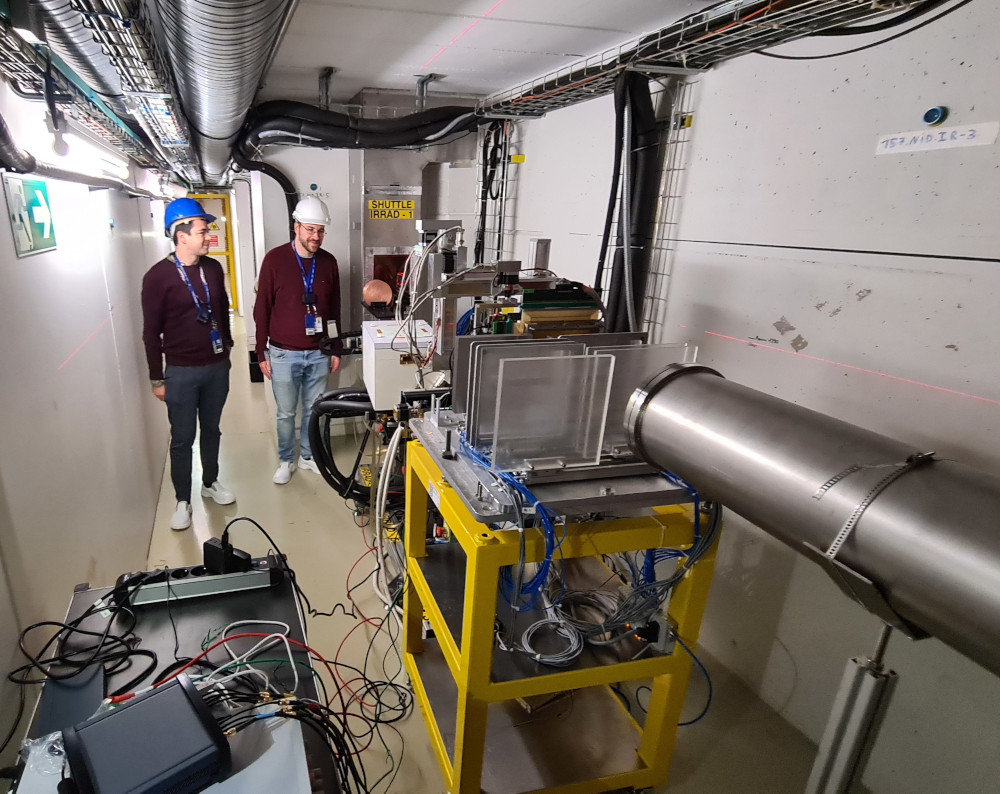

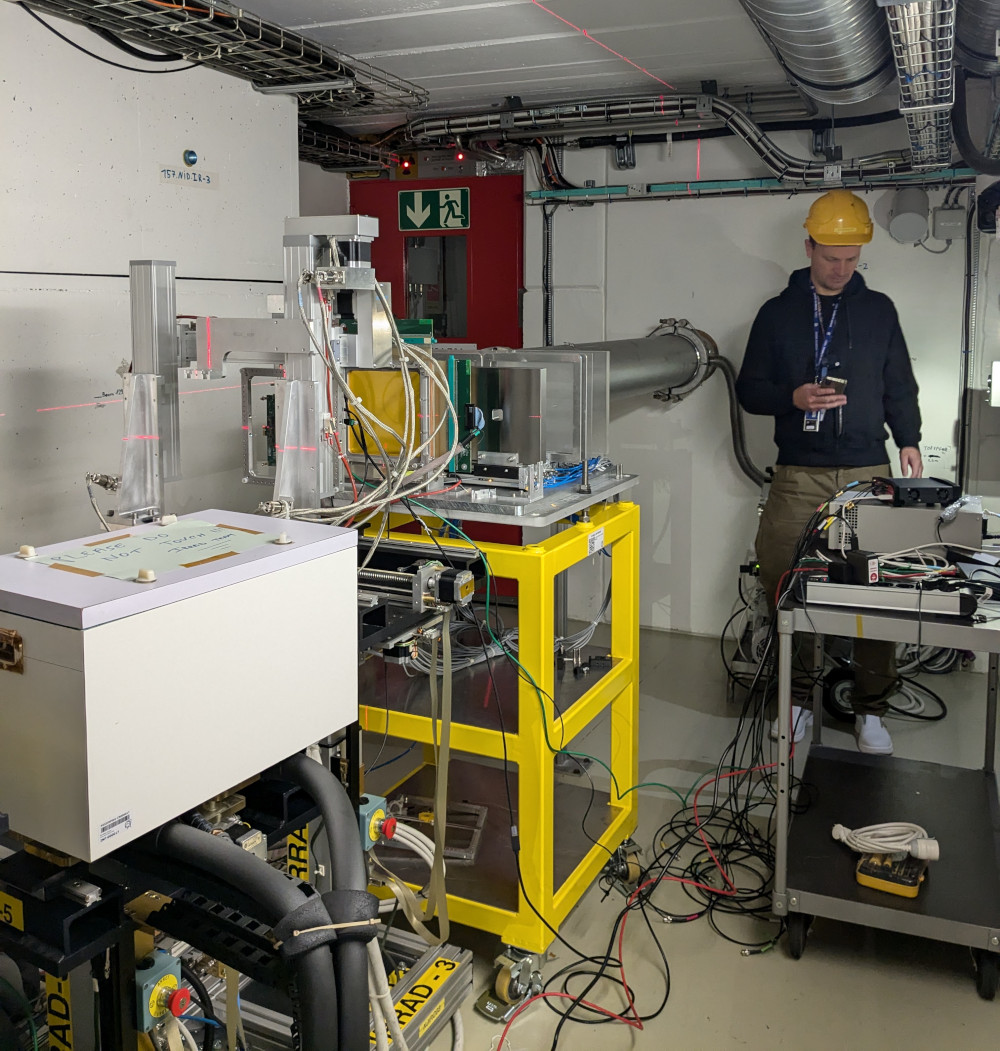

The very highly penetrating Pb ions used at HEARTS saved us from needing to decapsulate the ICs before testing. That convenience combined with the ability to remotely switch between large and small beam sizes allowed us to use the beam time efficiently while ensuring no IC was irradiated twice. We could target large groups of ICs in one go with the 75×75mm aperture and then switch to smaller 50×50mm or 25×25mm sizes to target tighter groups of ICs nestled amongst other components that we did not want to irradiate.

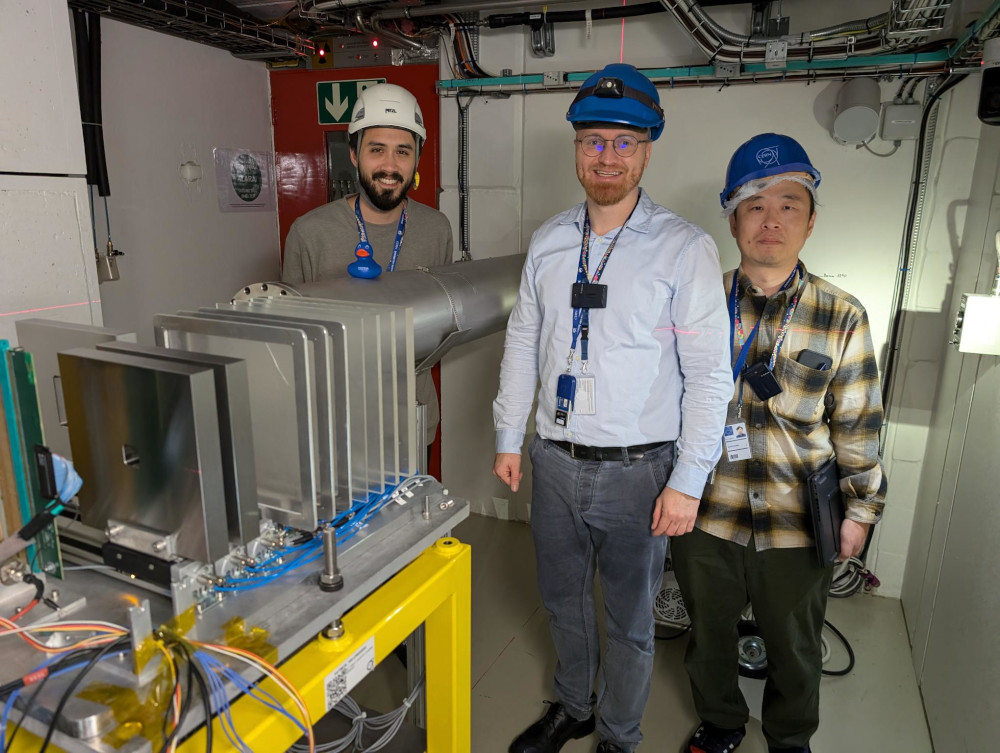

All that said, the convenience factor that proved to be most beneficial was the 24/7 staffing and maintenance. Our testing effort was an internal collaboration across 3 of our offices - Germany, United States, and Japan. An engineer from each office made the trip to CERN. To return home without meaningful results would have been devastating to say the least. But of course, things do go wrong from time to time when doing science and engineering. It just so happened that there was an issue with the beam integrity during our test run, which meant the beam needed to be shut down for maintenance for up to 12 hours. With 24/7 staffing at HEARTS and maintenance at CERN, however, the beam was back up and running later that same day, and we were able to complete our tests. What’s a more fun way to spend a Friday night than doing high energy particle testing late into the next morning?”

The HEARTS project is funded by the European Union under Grant Agreement No. 101082402, through the Space Work Programme of the European Commission.